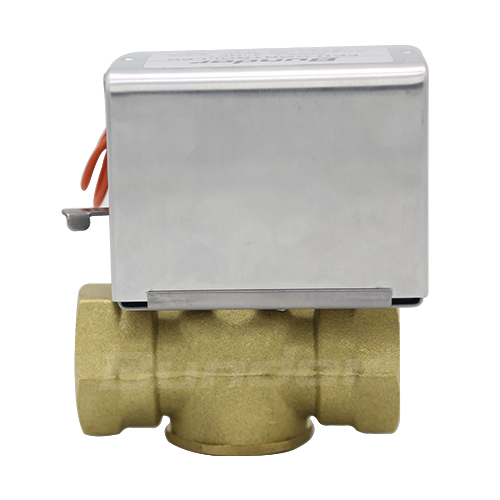

One-time hot forging brass valve body, higher density.

Size Range: DN15-DN25

Pressure: PN16

Body Materials: Brass 59-1

Seat Materials: NBR

Disc Materials: Brass+NBR

Stem Materials: Brass

One-time hot forging brass valve body, higher density.

Stainless steel base, aluminum shell.

Totally enclosed sealed hysteresis synchronous motor drive, stainless steel spring return.

Motor voltage and valve body connection can be made as per customer request.

The actuator can be installed onto valve body easily no need other plumbing tools.

| Material of Main Parts: | ||||

| Name | Body | Disc | Seat | Stem |

| Material | Brass 59-1 | Brass+NBR | NBR | Brass |

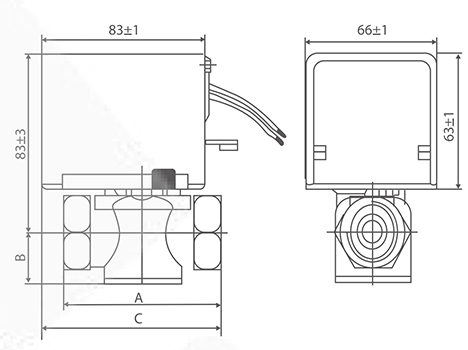

| Dimensions: | ||||

| DN | NPS(Inch) | A | B | C |

| 15 | 1/2" | 72 | 23 | 88 |

| 20 | 3/4" | 86 | 23 | 96 |

| 25 | 1" | 88 | 23 | 98 |

Check valves, globe valves, ball valves, filters, rubber joints, etc. are commonly used pipe accessories in fluid pipelines, with functions such as cut-off, regulation, diversion, prevention of backflow, pressure regulation, diversion, or pressure relief. It is commonly used to control the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil products, liquid metals, and radioactive media.

Threaded connection is a simple valve connection used for small diameter valves.It is different from other connections.

This article describes how to choose the right material for different valve body corrosion protection requirements.

We will introduce the wafer butterfly valve installation method.It is the most common type of industrial pipe valve.

Valve drive mode has manual, pneumatic, electric and so on.We can choose the driving mode according to different needs.

Copper sealed cast steel body gate valve is certain, cast iron or cast steel body can be surfacing copper alloy, but acc

Connection form: the connection form mainly has to the clamp, the flange, the clamp and so on, the different connection

The body material is ductile iron, while the traditional gate valve material is usually cast iron. The soft sealing gate

Valve industry belongs to equipment manufacturing industry and is a strategic target industry providing technical equipm

Market competition has led to China's valve round after round of fierce competition, the development trend of the futur

Bundor quickly dispatched a professional technical team to the customer's engineering site to investigate the problems.

Contact us now if you have any questions about our company and products.We will retain your information completely private.

You can send mail to info@bundorvalve.com or call us directly to Ms.Shirley. Business scopes spreads to middle China,West China,East China,South China and 76 countries &areas all over the world. We are familiar with all types of enterprises development strategy. Through reliable products and perfect services, the brand of Bundor has won extensive praise from customers.

Bundor has 117 products patents and passes CE, CU-TR, API, WRAS, ISO9007, ISO18001, ISO14001, AAA credit grade certificate. Strictly in accordance with ISO, API, JIS, DIN and other standards for valve production, the factory has a perfect enterprise standardization system, has more than 80 sets of high-precision mechanical equipment and quality testing equipment. Can provide more than 10000 kinds of valve models, with a perfect computer system, with independent product research and development capabilities.

Bundor valve is located in jinan area, tianjin city, is a collection of scientific research, design, production, sales and after-sales service as one of the professional valve manufacturers, its main export port is tianjin port. Tianjin port is an important comprehensive port and foreign trade port in north China. After the order is confirmed, production can be arranged in 24 hours to ensure the delivery time. Bundor valve always adhere to science and technology and quality peers, dare to innovate, the pursuit of excellence.

T/T, L/C, D/P D/A, PayPal, Western Union, Cash, Escrow are all allowed. Bundor valve has a set of perfect international trade system. From international trade marketing promotion to international trade negotiations, the group's international trade market of Bundor has been developing steadily in developing countries and regions such as Asia, Africa and Latin America, and has successfully opened markets in developed countries and regions such as Europe and America.

Founded in 1990s, Bundor is an experienced manufacturing and trading combo specialized in the research & development, production and sales of Butterfly valve, gate valve, check valve, globe valve and other valves. 26 years adhering to the principle of manufacturing process of competent valve fittings,the control of valve manufacturing throughout all the production processes, correctly understand customer requirements, and commit to provide products that ensure customer satisfaction.Our team