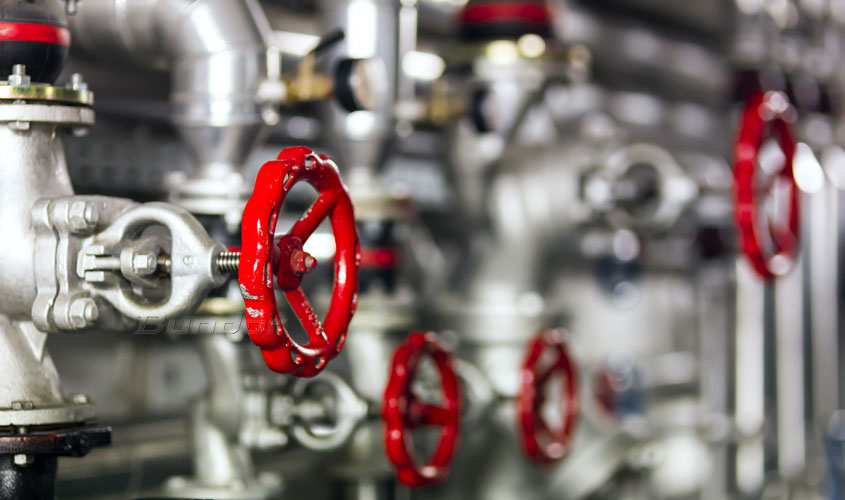

Inventory valve, some of the packing is not good, some with the use of media, this needs to change the packing.

Valve factory can not consider the use of thousands of units of different types of media, stuffing box is always filled with ordinary packing roots, but when used, must let the packing medium. When replacing the packing, press in round and round. Each lap seam with 45 degrees is appropriate, the circle and the circle open 180 degrees. The height of the packing shall take into account the space for the gland to continue to be pressed, and the proper depth of the packing chamber under the gland shall be given, which is generally 10-20% of the total depth of the packing chamber. For demanding valves, the joint Angle is 30 degrees. The joints between the rings are staggered by 120 degrees. In addition to the above packing, also according to the specific situation, using rubber o-ring forming packing. Wrap a PTFE raw material tape around the common asbestos packing to improve sealing and reduce electrochemical corrosion of the stem.

When pressing seasoning, turn the stem at the same time to keep all sides even and prevent it from being too dead. Tighten the gland evenly and do not tilt.