Soft sealing butterfly valve is small in size, light in weight and good in sealing performance. It is widely used in petroleum, chemical, metallurgy and municipal construction industries.

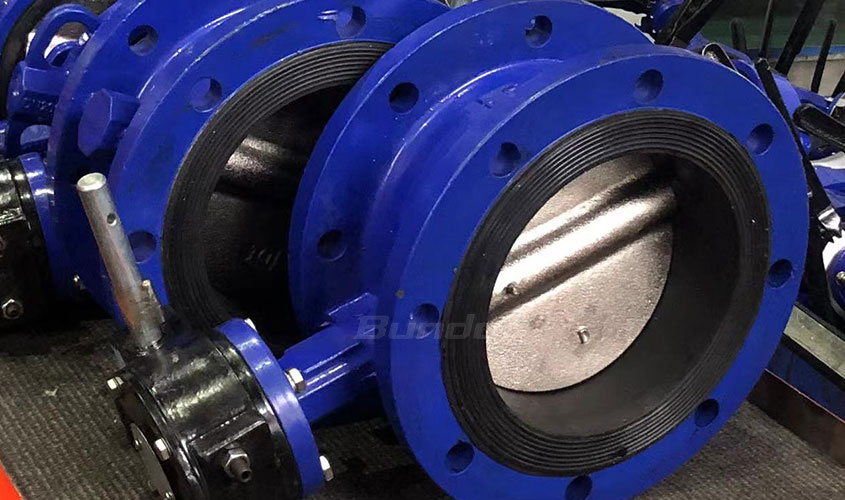

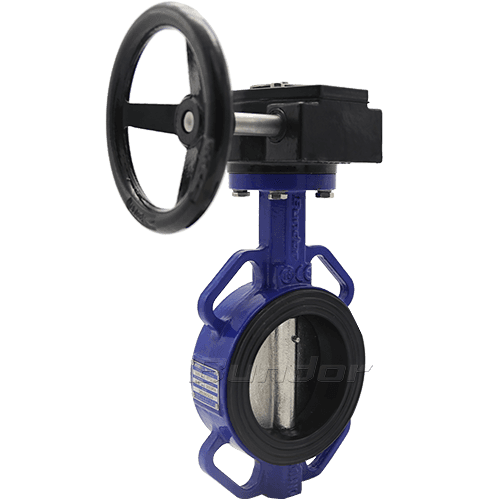

The connection methods of soft-seal butterfly valves are flange type and wafer type. In the process of operating and using soft-seal butterfly valves, some situations are often encountered. Let's take a look at the factors that affect the operation and use of soft-seal butterfly valves.

1 In the valve market, the most widely used sealing materials for soft-sealed butterfly valves are rubber and PTFE. These sealing materials can maximize the sealing performance of soft-sealed butterfly valves. No matter it is liquid or gas medium, zero leakage can be achieved. However, due to the limitations of the structural characteristics of these sealing materials, the soft-sealed butterfly valve cannot be used in high-temperature, high-pressure and high-wear circulation pipelines. If the medium in any of the above situations occurs in the pipeline, the soft-sealed butterfly valve will fail damage.

2 The sealing ring of the soft-seal butterfly valve is fixed on the valve disc. When the butterfly disc of the butterfly valve is in the open position, the fluid medium in the pipeline will scour the sealing surface of the butterfly valve positively, and under the long-term erosion and corrosion of the fluid medium, the soft sealing material will wear over time, which will affect the sealing performance of the soft sealing butterfly valve and cause leakage.

The factors that affect the operation of the soft-seal butterfly valve are the above two points. After the operator understands this information, he must pay attention to the use process, master the correct operation method of the soft-seal butterfly valve, and conduct regular maintenance. Let the soft sealing butterfly valve function to the greatest extent and serve our industrial production.