Water treatment engineering is to purify, soften, disinfect, and remove iron and manganese that does not meet the requirements. A project to remove heavy metal ions and filter. Simply put, a "water treatment project" is a project that uses physical and chemical means to remove some substances in the water that are not needed for production and life. It is a project of water quality conditioning such as sedimentation, filtration, coagulation, flocculation, corrosion inhibition and scale inhibition of water in order to be suitable for specific purposes.

What are the valves for water treatment projects?

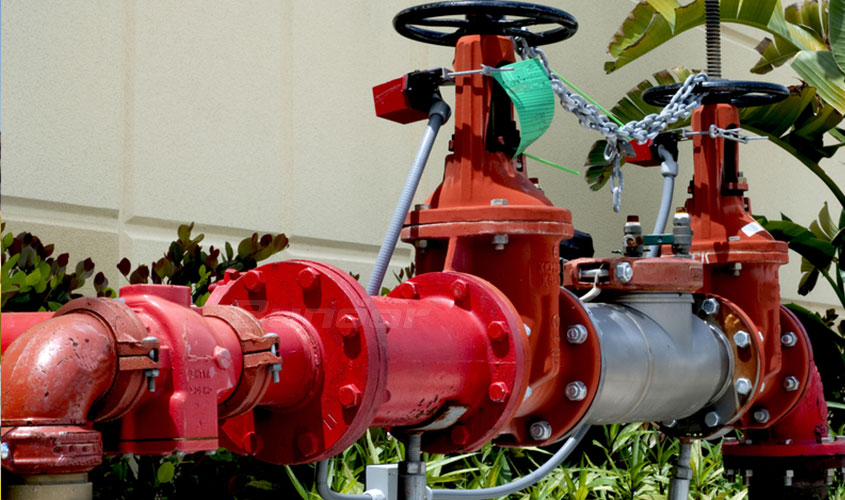

Gate valve: The function is to cut off the water flow. The rising stem gate valve can also see the valve opening size from the lifting height of the valve stem.

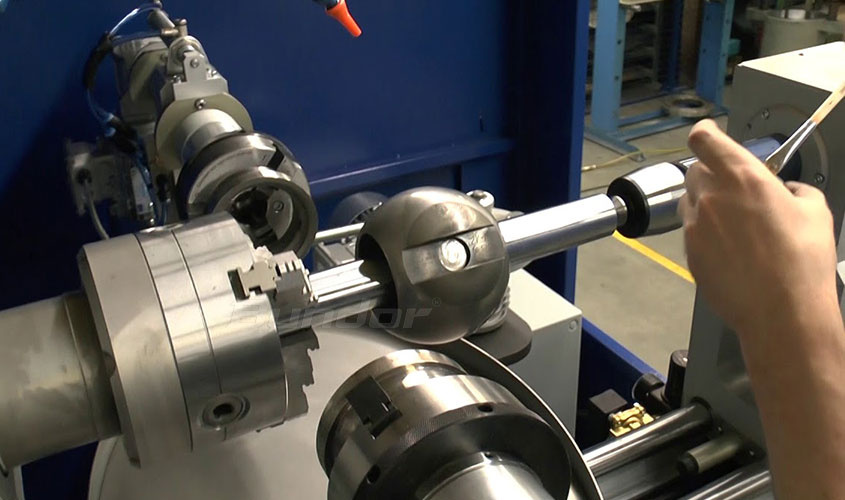

Ball valve: used for cutting off, distributing and changing the flow direction of the medium. Open/close valve for general use. Not suitable as a throttle valve, but in a partially open state, it can be used to reduce the pressure entering or exiting the system.

Stop valve: The main function of the water treatment pipeline is to cut off or connect the fluid. The regulating flow of the stop valve is better than that of the gate valve, but the stop valve cannot be used to adjust the pressure and flow for a long time. Otherwise, the sealing surface of the stop valve may be washed by the medium. Corrosion and damage the sealing performance.

Check valve: used to prevent backflow of media in water treatment pipelines and equipment.

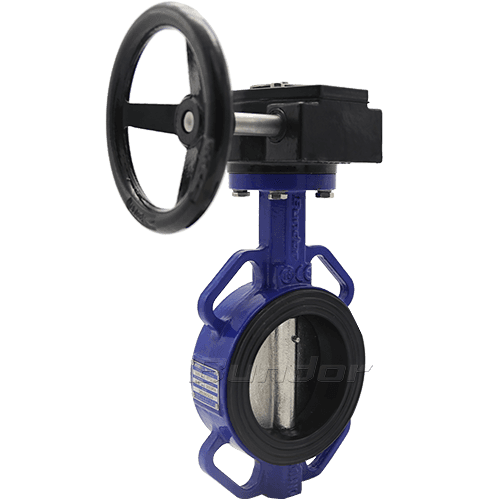

Butterfly valve: cut off and throttling function. When the butterfly valve is used for cutting, it is mostly used for elastic sealing, and the material is rubber, plastic, etc. When used for throttling, it is mostly used for metal hard sealing.