1 Flange connection type

Flange connection is the most used connection form between valve and pipeline or equipment. It refers to a detachable connection that is connected to each other by flanges, gaskets and bolts as a set of combined sealing structure.

Pipe flange refers to the flange used for piping in the pipeline installation, and refers to the inlet and outlet flanges of the equipment when used on the equipment. The flange connection is easy to use and can withstand greater pressure.

Flange connection can be applied to valves of various nominal sizes and nominal pressures, but there are certain restrictions on the operating temperature. In high temperature conditions, the flange connecting bolts are prone to creep and cause leakage. Generally, the flange connection is recommended to be used at a temperature less than or equal to 350°C.

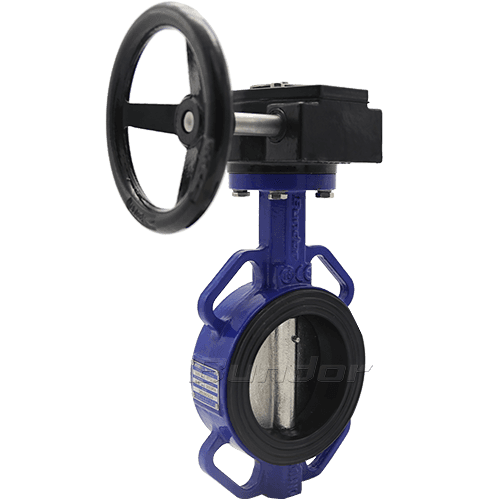

2 Wafer connection type

A connection form in which the valve and two pipes are directly clamped together with bolts.

The different connection methods of the valve are suitable for different working conditions. It is recommended that the valve user treat it according to the specific situation.