The heat pipe network is also called the heat pipe. It is a heating pipe that leads from the boiler room, the direct combustion engine room and the heating center, and from the heat source to the thermal inlet of the building. A plurality of heating pipes form a pipe network.

What are the valves used in the heat pipe network?

The shut-off valve shall be installed at the starting point of the main line, trunk line and branch line of the heat network.

The hot water heating network trunk line should be equipped with a segmented valve. The spacing of the segmented valves is preferably the following. The distance between the conveying trunks should be 2000-3000m. The spacing of the transmission and distribution trunk lines should be 1000-1500m. The steam heat network can be installed without a segmented valve. The cross-section valve connecting the main line of the heat source of the multi-heat source heating system and the loop line of the ring pipe network should adopt a two-way sealing valve.

A bypass valve shall be installed on the pipe with a working pressure greater than or equal to 1.6 MPa and a nominal diameter greater than or equal to 500 mm. The diameter of the bypass valve can be selected as one tenth of the diameter of the valve.

When the heating system has limited water supply capacity and needs to control the pipe water filling flow rate or the steam pipe to start the heating pipe to control the steam volume, the pipeline valve should be equipped with a smaller diameter bypass valve as the control valve.

When the dynamic hydraulic analysis needs to extend the closing time of the delivery trunk section valve to reduce the pressure transient value, it should be solved by using the main valve parallel bypass valve. The diameter of the bypass valve can be taken as a quarter of the diameter of the main valve. The main valve and the bypass valve should be interlocked. The bypass valve must be in the open state for the main valve to close. The bypass valve can only be closed after the main valve is closed.

For valves with a nominal diameter greater than or equal to 500 mm, an electric drive should be used. For valves operated remotely by the monitoring system, the bypass valve should also be powered by an electric drive.

The heat pipe network generally refers to the part of the heat exchanger station outlet to the user's indoor riser. The valves used are as follows:

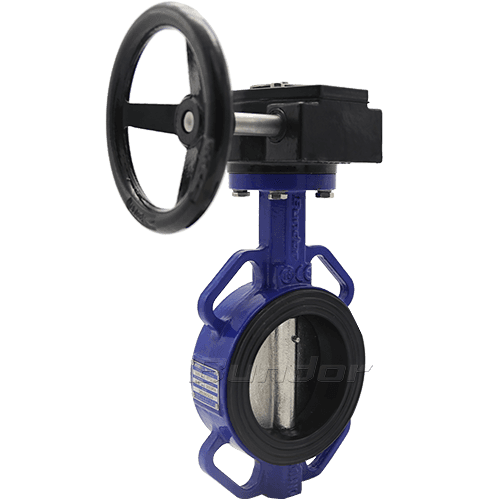

1. The most common use of the circulation pump outlet of the heat exchange station is the butterfly valve and the gate valve. The specifications are selected according to the pressure of the heat pipe network.

2. The most commonly used heat exchange station to the user's outdoor is the gate valve and butterfly valve. If you need to add a flow valve, consider adding a flow valve. For the drain valve, a small cast iron gate valve is generally used.

3. The brass ball valve or brass gate valve is generally used in the user's room. Brass ball valves or brass gate valves are required to add a drain valve.

4. Pressure gauges and valves used in thermometers or sensors are usually included. And we usually select them according to the package.

The above is all we have introduced for you. Bundor Valve is a professional valve manufacturer. We can provide you with a complete set of thermal pipe network valve solutions. If you have a need to purchase valves, please contact us.