What valve is used in the sludge line? To understand this, let's first understand sludge and sludge treatment.

Sludge is a product of sewage treatment. It is an extremely complex heterogeneous body composed of organic residues, bacterial cells, inorganic particles, colloids and other substances. The main characteristics of the sludge are as follows. It has a high water content (up to 99% or more). The high content of organic matter makes it easy to rot and smell. And the particles are finer, and it has a smaller specific gravity and is in a gelatinous liquid state. It is a thick material between liquid and solid that can be transported by pump, but it is difficult to separate it by solidification.

Sludge treatment is a process of reducing, stabilizing and detoxifying sludge. The higher the degree of sewage treatment, the more sludge residue that needs to be treated. Unless it is treated with land treatment or sewage ponds, the general sewage treatment plant must have a sludge treatment facility. For modern wastewater treatment plants, sludge treatment and disposal has become the most complex and costly part of the operation of wastewater treatment systems.

Before we process the sludge, we must first understand the classification of the sludge to determine the sludge treatment method:

1. Treatment of physicochemical sludge discharged from the sedimentation tank or concentration tank of the waterworks.

Classification of sludge: It is a medium-fine particle size organic and inorganic mixed sludge with general compressibility and dewatering performance.

2. Treatment of residual activated sludge discharged from the secondary sedimentation tank of the domestic sewage treatment plant.

Classification of sludge: It is a hydrophilic, fine-grained organic sludge with poor compressibility and poor dewatering performance.

3. Treatment of physicochemical and biochemical mixed sludge discharged from the concentration tank produced by industrial wastewater treatment.

Classification of sludge: It is a medium-fine-grain mixed sludge. The dehydration performance of the fiber-containing body is good, and the rest of the compressibility and dewatering performance are generally.

4. Treatment of physicochemical fine-grained sludge produced by physical and chemical processes produced by industrial wastewater treatment.

Classification of sludge: It is a fine-grained inorganic sludge with general compressibility and dewatering performance.

5. Treatment of physicochemical precipitated coarse-grained sludge produced by industrial wastewater treatment.

Classification of sludge: It is a coarse-grained hydrophobic inorganic sludge with good compressibility and dewatering performance.

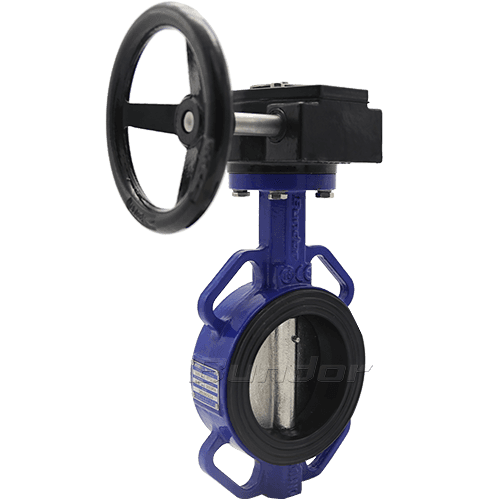

The valves that can be used on the sludge treatment pipeline include hard-sealed butterfly valves, ball valves, knife gate valves, and mud valves. Which kind of valve is needed depends on the actual conditions of the working conditions.

If you have a purchase request for a sludge valve, you can contact a Bundor valve. Bundor Valve will make a reasonable valve selection according to your specific working conditions.

In addition, the domestic and foreign distributors of the Bundor Valve are in hot recruitment! If you need to know more, please consult the online customer service of the Bundor Valve!