A triple eccentric sealing butterfly valve is one type of butterfly valve. Its unique sealing form and sealing structure are continuously improved and upgraded to obtain a better sealing effect. It has great reforms in the performance of high temperature and corrosion resistance. Let's take a look at its product upgrade process.

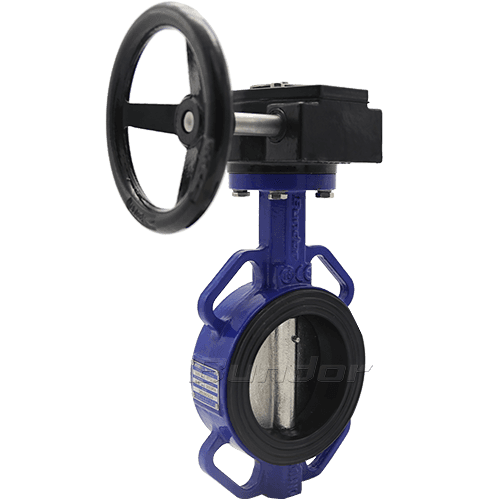

The single eccentric soft sealing butterfly valve in the butterfly valve is the first to be loved by customers. Because the design of the soft seal can make the product have a good sealing effect. The single eccentricity is that the sealing section of the valve seat is opposite to the center of rotation of the valve stem, so that the sealing surface of the disc gradually disengages from the sealing surface of the valve seat during the opening process. When the disc is rotated to 20~25, the sealing surface of the disc is completely separated from the sealing surface of the valve seat, so that the relative mechanical wear and compression between the two sealing surfaces are greatly reduced during the opening process of the butterfly valve. Thereby the sealing performance of the butterfly valve is improved. This design relies mainly on the compression between the disc and the seat to produce elastic deformation to ensure the sealing of the butterfly valve.

The double eccentric sealing butterfly valve is upgraded on the basis of a single eccentric butterfly valve in order to achieve the effect that the sealing surface of the butterfly plate is separated from the sealing surface of the valve seat faster than the single eccentric structure. We offset the center of rotation of the disc with the centerline of the valve runner so that the butterfly valve creates a cam effect during the opening process. When the disc is rotated to 8°~12°, the two sealing faces can be completely disengaged. The biggest advantage of this structure design is to further reduce the mechanical wear and extrusion deformation between the two sealing faces, so that the sealing performance of the butterfly valve is improved and the service life is increased.

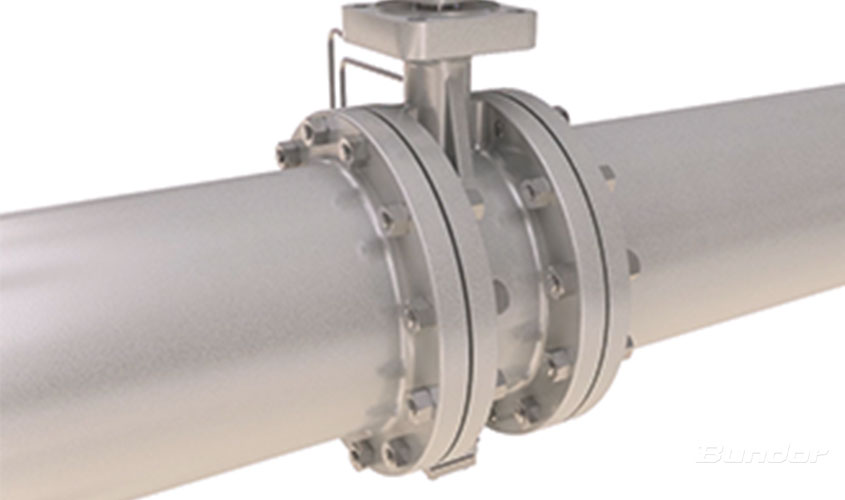

The triple eccentric sealing butterfly valve was upgraded again on the basis of the double eccentric butterfly valve. We create an angular eccentricity by centering the centerline of the seat seal face with the valve centerline, resulting in a third eccentricity. In this way, during the opening process, the sealing surface of the disc plate is instantly released from the sealing surface of the valve seat, and the sealing surface of the valve seat is contacted and pressed at the moment of closing. This unique eccentric design makes full use of the cam benefit, so that the mechanical friction and scratch between the two sealing faces of the butterfly valve sealing pair can be completely eliminated and the possibility of wear and leakage is eliminated. The seal of the product changes from a squeeze seal to a torque seal. The adjustment of the sealing specific pressure can be achieved by adjusting the applied driving torque, so that the sealing performance and service life of the triple eccentric sealing butterfly valve are greatly improved. At the same time, it ensures the tight sealing, and also improves the performance of the sealing material of the single eccentric soft sealing butterfly valve and the double eccentric soft sealing butterfly valve which cannot withstand high temperature and wear resistance.

At present, the three eccentric sealing butterfly valves are widely used in medium pipelines of urban construction, petrochemical, metallurgy, electric power and other industries to cut off or adjust the flow of the best device. Its structure itself is the most ideal opening and closing part in the pipeline, and it is the development direction of the pipeline opening and closing parts. If you need a butterfly valve product, please look for the Bundor valve. We have 24 years of butterfly valve production experience to make you more assured.