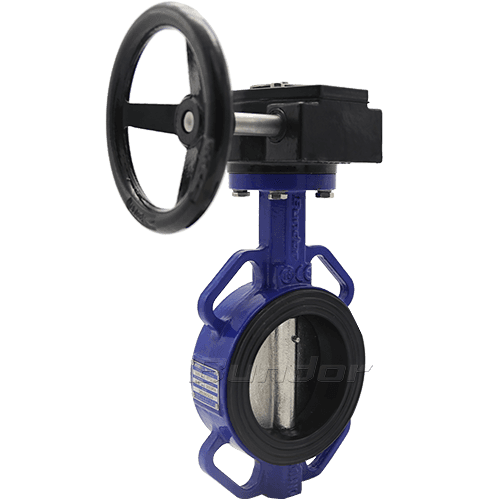

Butterfly valve has the advantages of good flow regulation function and good sealing performance, so it has become one of the fastest growing valve varieties in the past decade. The butterfly valve has simple and compact structure, light weight, convenient operation, reliable performance, complete functions, beautiful appearance and convenient maintenance. It is very popular among customers. In actual working conditions, if you want the flange butterfly valve to achieve effective leakage prevention, the correct installation method is very important. Today, the Bundor valve will share with you the installation precautions for the flange butterfly valve. It is as follows:

1.Before installation, you must carefully check whether the valve's mark and certificate meet the requirements for use. For example, when installing the Bundor D342X flange rubber sealing butterfly valve, we need to check whether the brand and model of the product match the required valves of the pipeline, and clean it after verification. Here we have to mention the storage of the flange butterfly valve. Butterfly valves that are not currently installed must be stored in a dry room. Butterfly valves with long storage time should be cleaned regularly, blown dry, and coated with anti-rust oil. The flange sealing surface should be protected by a blind plate.

2.We need to install it according to the medium and its flow direction. For example, if the valve needs to pass water, we need to use EPDM rubber gasket. When tightening the bolts, we need to use the symmetrical or star method of torque. If the valve needs to pass through the corrosive medium, we need to use a PTFE gasket. When tightening the bolts, we use symmetrical or star-shaped torque.

3.When the flanged butterfly valve and the connecting bolt of the pipe are installed, the single part cannot be tightened at one time. We should tighten them at the same time in a diagonal direction to prevent the flange joint from leaking due to uneven force.

4.When the butterfly valve is installed, the butterfly plate should be in the closed position to prevent debris from entering and wearing the sealing surface. When the user tests the pressure, the flange should also be clamped at both ends.

5.When the valve is connected with the pipeline, we should choose the flange of the appropriate specification to ensure the effective sealing surface.

6. Before the electric flange butterfly valve is turned on for the first time, it needs to be manually adjusted to 1/3 of the off position. And we need to check if the direction of the indicator disc is consistent with the opening direction of the valve.

7. If the flange butterfly valve fails during use, stop using it immediately.

When we master the above correct installation method, the flange butterfly valve will be more confidential and durable in the application. If you are looking to purchase high quality flanged butterfly valves, Bundor valve will be your best choice. The sealing surface of the Bundor flange butterfly valve has high processing precision, small opening friction and light closing. It not only has stable self-sealing performance and sealing performance, but also has the self-locking feature of tighter and tighter. It is also suitable for a variety of media such as gas, steam, air, and water. You are welcome to consult us.