The common faults of the valve are leakage, failure of the opening and closing parts, etc. One of the most important reasons for valve failure is that the valve is not properly maintained. The valve is an important part of the pipeline transportation system. It is necessary to maintain and maintain it to make the valve better serve us. At the same time, it can also prevent the occurrence of valve failures from the source and reduce production accidents caused by valve failures. Therefore, this article will talk about the maintenance methods of common valves.

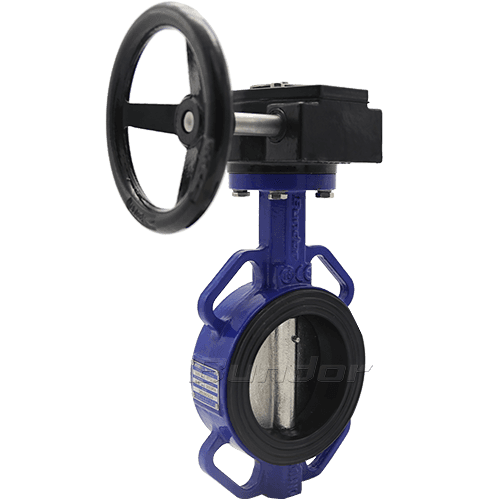

1. For valves that are not used for a long time, be sure to clean them regularly to remove dirt and dust on the exposed surface of the valve. At the same time, seal them to ensure that the inside of the valve is clean and dry. Store the valve neatly in a ventilated and dry place indoors. Do not stack or store it in the open air. The butterfly valve is the easiest to store when stored. Let the disc be closed. For gate valves, globe valves and check valves, both ends of the passage are blocked during storage and the valve plate is closed. The ball valve is stored in such a way as to block both ends and open the ball valve.

2. Before installing the valve, it is necessary to check the pressure and diameter of the valve again and clean the dirt on the valve during transportation.

3. When installing the valve, install it correctly according to the connection method of the valve. Usually the commonly used valves can be installed at any position of the pipeline, but it is necessary to consider whether the operator's operation is convenient after installation, and whether it is convenient for future valve maintenance.

4. When the gate valve and the ball valve are working, they are only fully open and fully closed. It is not allowed to use the regulating flow. Otherwise, the sealing surface will be severely washed and eroded, and the opening and closing parts of the valve will wear more.

5. When the handle valve and the handwheel valve are opened or closed, no lever, wrench or other tools can be used to avoid damage to the valve.

6. Evenly tighten the bolts on the valve packing gland. Do not rub the gland, so that the gland is tilted, which will hurt or hinder the movement of the valve stem and cause the valve to leak.

7. During use, the valve should be regularly maintained and maintained to keep the valve clean. The transmission part should be lubricated regularly. Once the valve is found to be faulty, it must be stopped immediately to find out the cause of the failure and clean up the fault.