Valves commonly used in water supply and drainage piping systems include butterfly valves, gate valves, globe valves, and check valves. This article introduces the common water supply and drainage system valves.

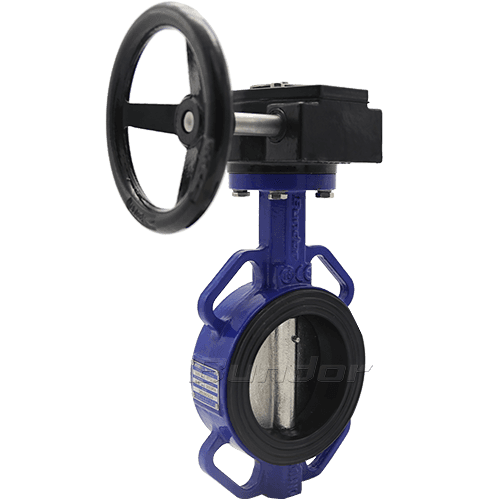

1. Butterfly valve: It is a simple regulating valve. It is generally used in the pipeline of low-pressure medium. It is used for cutting and intercepting. It is also one of the common valves of the water supply and drainage pipeline system. It regulates and intercepts the flow of water on the water supply and drainage pipeline. . The butterfly valve is small in size, light in weight and easy to install and operate. However, its opening and closing torque is large.

According to the connection method, the butterfly valve can be divided into a pair of butterfly valves and a flange butterfly valve. According to different driving methods, it can be divided into handle butterfly valve, turbo butterfly valve, electric butterfly valve, pneumatic butterfly valve, etc.

2. Gate valve: It can only be used as a kind of valve to cut off the flow of the pipeline medium. The structure of the gate valve is more complicated, and it can only be fully open and fully closed, and the opening and closing torque is small. The fluid resistance in the pipe is small and can flow in both directions. The gate valve is most suitable for mediums containing no particulate impurities such as water. Because the sealing surface of the ram is easy to wear due to friction with impurities or particles in the medium, and impurities are deposited on the bottom of the valve body, which will affect the sealing performance of the gate valve, resulting in a defect that the valve is not tight.

Gate valves are only suitable for use in lines that require normally open or normally closed. Because if the gate valve is frequently opened and closed, the valve plate may fall off and the system may lose control.

Gate valves can be divided into parallel plate gate valves and wedge plate gate valves according to the difference of gates. According to the difference of the valve stem, it can be divided into a outside stem gate valve and a non ring stem gate valve.

3. Globe valve: Similar to the gate valve, the functions of the two are similar when the medium in the pipeline is cut off. However, the difference between the globe valve and the gate valve is that the structure of the shut-off valve is simpler and the maintenance is more convenient, but the force used by the switch valve is greater than that of the gate valve. In addition, the shut-off valve belongs to the one-way valve, and the valve body should be carefully installed according to the valve body. The indications on the operation shall not be reversed.

4. Check valve: also known as non-return valve, one-way valve, has strict directionality, the regulation only allows the medium to flow in one direction. The purpose of the check valve is in the pipeline where the medium is water, and is mainly used to prevent backflow of water.

Commonly used check valves include butterfly check valves, muffler check valves, and swing check valves. The installation should be based on the type of valve to determine whether it is installed on a vertical pipe or a horizontal pipe. It must be installed in strict accordance with the direction marked by the arrow of the valve body, and it can not be reversed.