You can send mail to info@bundorvalve.com or call us directly to Ms.Shirley. Business scopes spreads to middle China,West China,East China,South China and 76 countries &areas all over the world. We are familiar with all types of enterprises development strategy. Through reliable products and perfect services, the brand of Bundor has won extensive praise from customers.

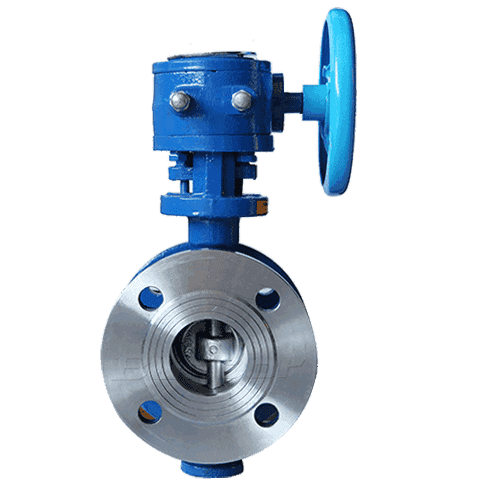

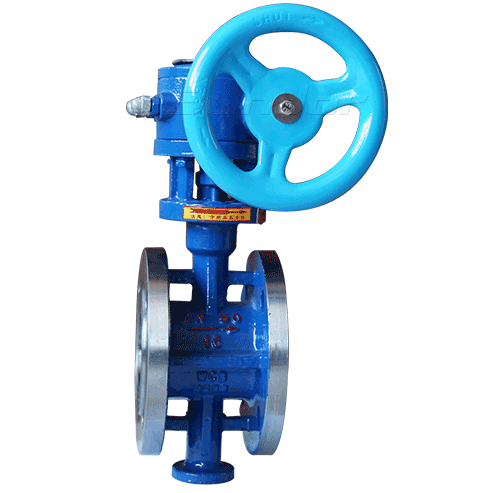

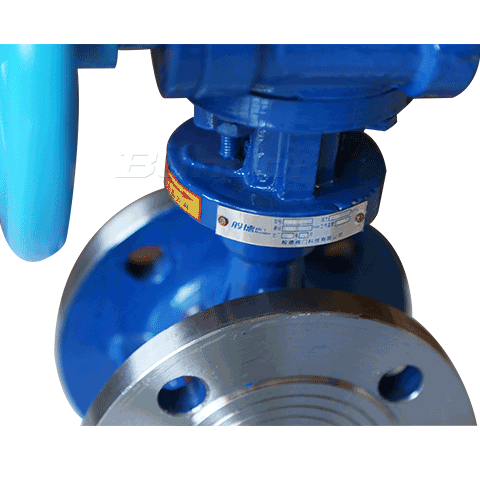

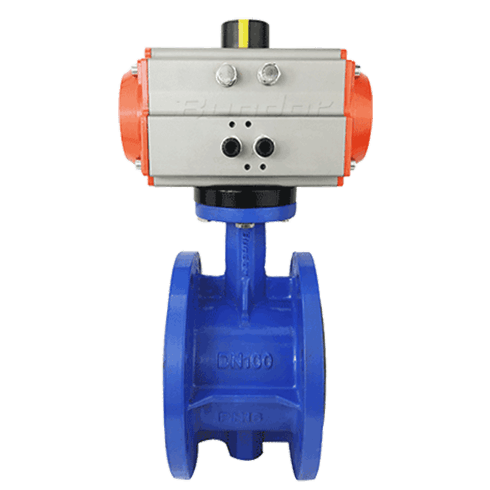

Bundor has 117 products patents and passes CE, CU-TR, API, WRAS, ISO9007, ISO18001, ISO14001, AAA credit grade certificate. Strictly in accordance with ISO, API, JIS, DIN and other standards for valve production, the factory has a perfect enterprise standardization system, has more than 80 sets of high-precision mechanical equipment and quality testing equipment. Can provide more than 10000 kinds of valve models, with a perfect computer system, with independent product research and development capabilities.

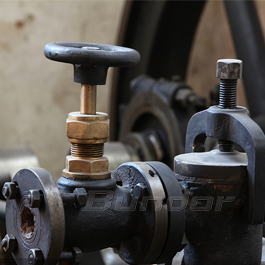

Bundor valve is located in jinan area, tianjin city, is a collection of scientific research, design, production, sales and after-sales service as one of the professional valve manufacturers, its main export port is tianjin port. Tianjin port is an important comprehensive port and foreign trade port in north China. After the order is confirmed, production can be arranged in 24 hours to ensure the delivery time. Bundor valve always adhere to science and technology and quality peers, dare to innovate, the pursuit of excellence.

T/T, L/C, D/P D/A, PayPal, Western Union, Cash, Escrow are all allowed. Bundor valve has a set of perfect international trade system. From international trade marketing promotion to international trade negotiations, the group's international trade market of Bundor has been developing steadily in developing countries and regions such as Asia, Africa and Latin America, and has successfully opened markets in developed countries and regions such as Europe and America.